Worm Gear Gears

The Worm Gear Ratio Calculator is a valuable tool designed to determine the gear ratio between a worm gear and a worm wheel (or gear) in mechanical systems. This ratio helps in understanding the rotational speed and torque transfer between these interlocking gears.

Worm Gear Design Calculation Pdf Converter highpowerdial

The worm and hob lead angle calculator calculates the lead angle for a worm gear or gear hob based on its diametral pitch (1/in) or module (mm). This ultimately controls the spacing between teeth on the worm (just like the threads per inch, or pitch, of a screw). The pitch diameter of a worm gear or gear hob can be used as its effective.

Download Worm Gear Calculator Program free software rutrackerxtra

Worm gear sets are generally rated by their capacity to handle a particular level of input power, output power, or allowable torque at a particular speed for the input or output shaft. The AGMA power rating is based on pitting and wear resistance, as this is the usual failure mode for worm sets.

Worm Gear Design Calculation Pdf File rangmillionaire

Worm gears are quiet in operation. Worm gears at the higher ratios are inherently self locking - the worm can drive the gear but the gear cannot drive the worm. A worm gear can provide a 50:1 speed reduction but not a 1:50 speed increase..(In practice a worm should not be used a braking device for safety linked systems e.g hoists. .

ZAR3 Worm Gear Calculation

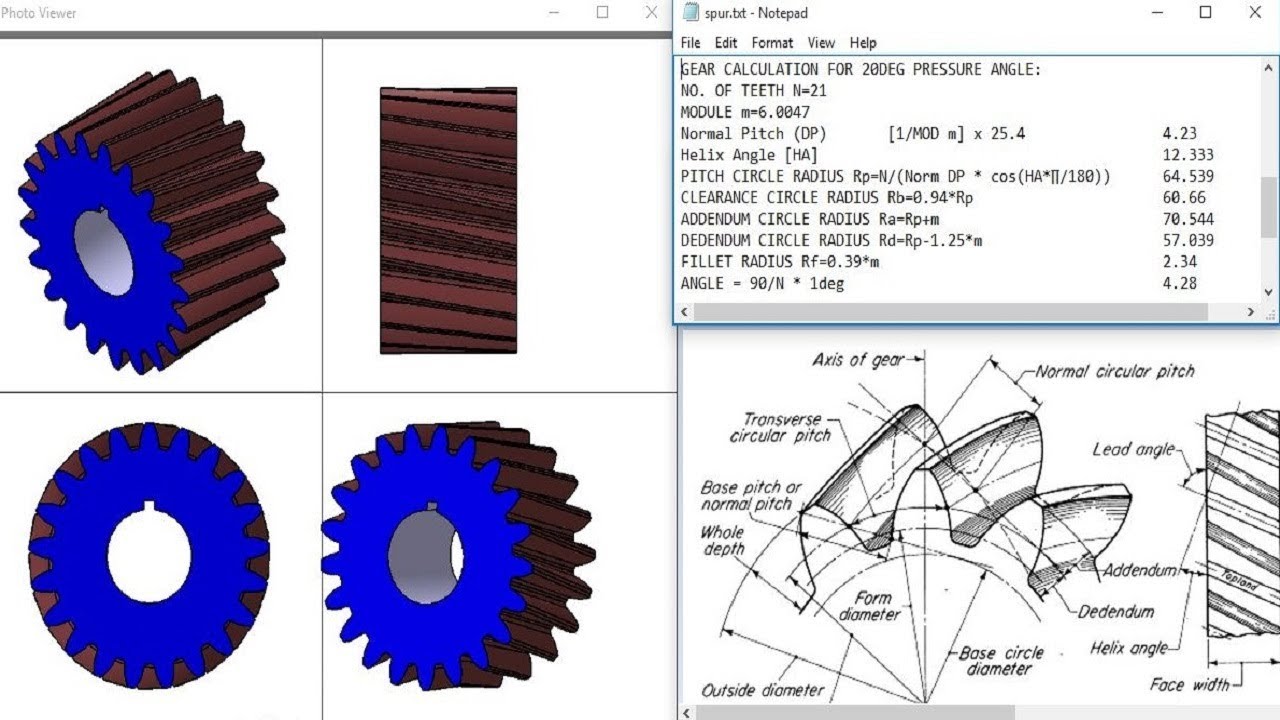

Free Gear Calculator What is a gear calculator ? The gear calculator is a comprehensive software which, after inputting various parameters related to gear calculations, computes on-line automatically gear sizes, strengths, working forces, tooth forms, backlash conversions, etc.

Composite Worm Gears Extend Wear Life in Tough Applications

Worm gearing is a special case of screw gearing with the angle of axes 90° and a low number of pinion/worm teeth (mostly z1=1-4). Worm gearing types are distinguished by shape as follows: Globoid worm/cylindrical wheel (not used) Types of cylindrical worms: .

Worm Gear What Is It? How Is it Made? Types Of, Uses

Instant Throated Worm Shaft Calculator The following online calculator computes the parametric equations of a globoid (throated) worm shaft based on its basic dimensions, shape and desired number of teeth in the matching gear wheel. Globoid Worm Generating Script

Worm Gear Design Calculation Pdf ovasgsynergy

This online calculator computes the raw toothed outlines of two meshing non-circular gears based on the polar equation of Gear 1 's pitch curve, the desired Gear 1 -to-Gear 2 pitch length ratio, desired number of teeth, and other parameters.

Worm Gear Calculation PDF Gear Force

The Worm Gear Torque Calculator is a tool used to calculate the torque or rotational force required to drive a system using a worm gear mechanism. It employs a formula that considers parameters such as the worm gear's lead angle, pitch diameter, and coefficient of friction to determine the torque required for efficient operation.

How to Calculate the Centre to CentreDistance between Worm and Wrom

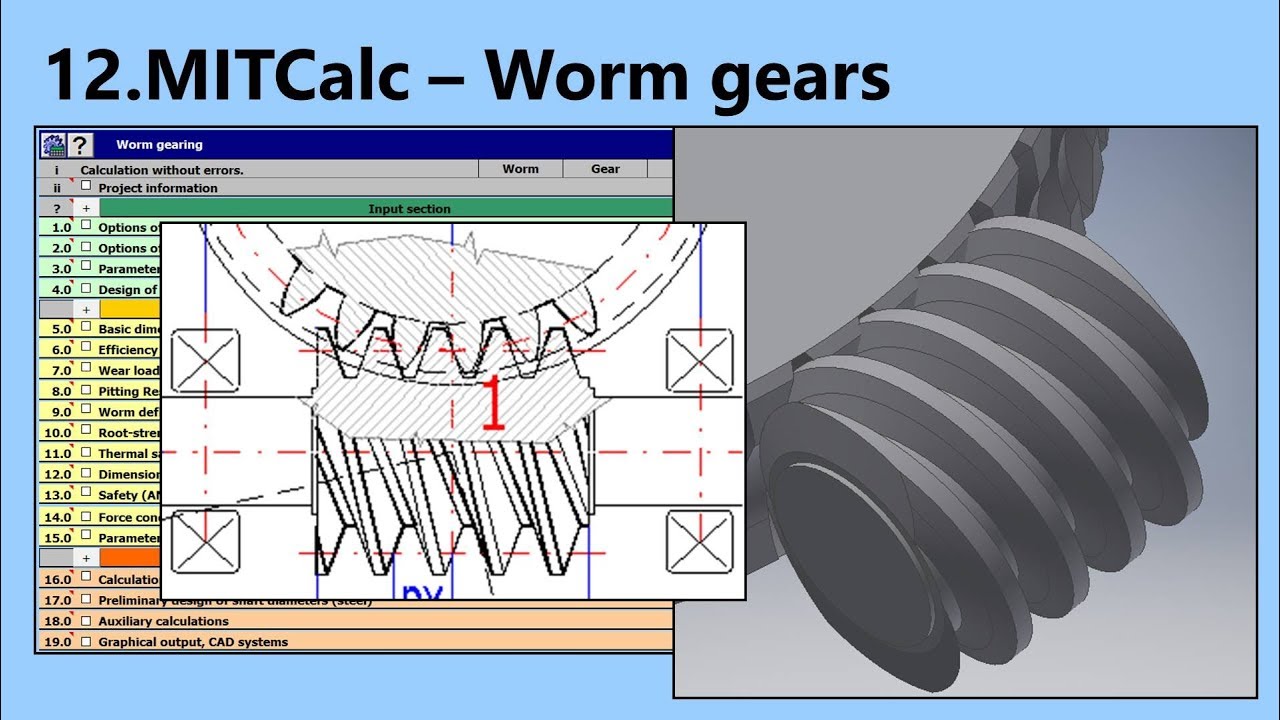

The calculation includes automatic design and solve dimensions, efficiency, losses, wear and pitting resistance, heating, safety, forces and more. MITcalc - Worm gear, geometric design and strength check.

Competence in worm gear units for more than 120 years • AUMA Drives

This calculator will determine the axial thrust or load applied on a screw (worm gear) thread. Reference: Schaum's Outline Machine Design. Enter desired data within the boxes, calculations should be automatic. This calculator requires a java enabled browser. Open Screw Worm Gear Gear Axial Force Equation and Calculator

How to Calculate Worm Gear Ratio? YD FORCE

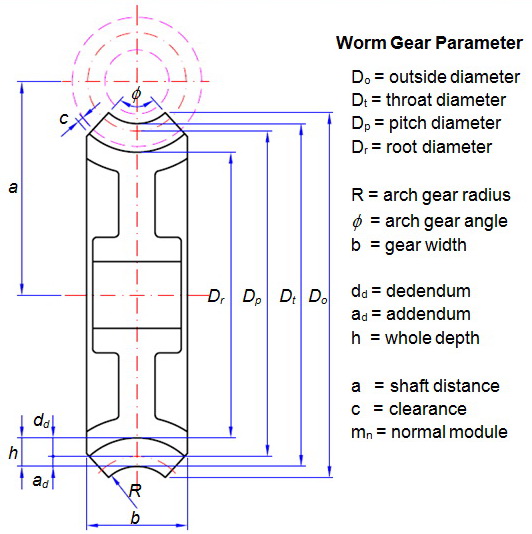

Worm and WormGear Design Equations and Calculator Gears Engineering and Design Equations for American Standard Fine Pitch Worms and Wormgears Per. ANSI B6.9 P = Circular pitch of wormgear P = axial pitch of the worm P x, = in the central plane P x = Axial pitch of worm P n = Normal circular pitch of worm and wormgear = Px cos λ = P cos ψ

ZAR3 Worm Gear Calculation

Gears Engineering and Design. Worm Gear Sizing Calculations and WormGear Nomenclature. ALL calculators require a Premium Membership. Preview Wormgear Design Calculator. Materials Factor (C s) C <= 3 in. sand-cast. d G <= 2.5 in. d G > 2.5 in.

Worm gear design calculation pdf sanycpa

In this video we first hand draw a basic worm gear meshed with a worm wheel. Then we take a look at the function of a worm gear assembly and how to find the.

Worm Gear Calculation and Design (MITCalc12) YouTube

1 Scope. This document specifies formulae for calculating the load capacity of cylindrical worm gears and covers load ratings associated with wear, pitting, worm deflection, tooth breakage and temperature. Scuffing and other failure modes are not covered by this document. The load rating and design procedures are only valid for tooth surface.

ZAR3 Worm Gear Calculation PDF Gear Windows Vista

ZAR3+ generates true-scale drawing of worm and worm gear. ZAR3+ provides an additional input window for modifications of tooth height factors and profile shift coefficient x. These functions are useful for design of complementary gears of steel worm and plastic worm gear. ZAR3+ calculates tooth thickness and over pin/ball diameters (OPD).